Spindle motor

Spindle motor, also sometimes called the spindle shaft, is responsible for turning the hard disk platters, allowing the hard drive to operate. The spindle motor is sort of a “work horse” of the hard disk. It’s not flashy, but it must provide stable, reliable and consistent turning power for thousands of hours of often continuous use, to allow the hard disk to function properly. In fact, many drive failures are actually failures with the spindle motor, not the data storage systems.

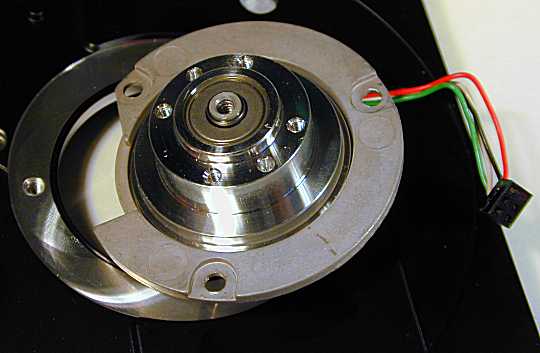

A hard disk spindle motor, stripped of its platters and other components, and detached from the drive’s base casting. You can see that it attaches with three screws around its perimeter. The shiny metal is the shaft, which rotates; the dull metal is the base of the motor. The six small screw holes on the top of the shaft are for securing the platters. You can also see a large screw hole in the center top of the shaft, which is used to attach the top cover to the spindle shaft for added stability. the four wire connector attaches to the hard disk logic board.For many years hard disks all spun at the same speed. In the interests of performance, manufacturers have been steadily ratcheting up their products’ spin speeds over the last few years. These higher-speed spindles often have issues related to the amount of heat and vibration they generate. The increased performance and also the new potential issues related to the spindle motor have given it renewed attention in the last few years.

Spindle motor has several important demands placed upon it. First, the motor must be of high quality, so it can run for thousands of hours, and tolerate thousands of start and stop cycles, without failing. Second, it must be run smoothly and with a minimum of vibration, due to the tight tolerances of the platters and heads inside the drive. Third, it must not generate excessive amounts of heat or noise. Fourth, it should not draw too much power. And finally, it must have its speed managed so that it turns at the proper speed.

To meet these demands, all PC hard disks use servo-controlled DC spindle motors. A servo system is a closed-loop feedback system; this is the exact same technology as is used in modern voice coil actuators, and I discuss how servo systems work in detail in that section. In the case of the spindle motor, the feedback for the closed-loop system comes in the form of a speed sensor. This provides the feedback information to the motor that allows it to spin at exactly the right speed.

All hard disk spindle motors are configured for direct connection; there are no belts or gears that are used to connect them to the hard disk platter spindle. The spindle onto which the platters are mounted is attached directly to the shaft of the motor. The platters are machined with a hole the exact size of the spindle, and are placed onto the spindle with separator rings (spacers) between them to maintain the correct distance and provide room for the head arms. The entire assembly is secured with a head cap and usually, lots of small Torx screws.

The amount of work that the spindle motor has to do is dependent on a number of factors. The first is the size and number of platters that it must turn. Larger platters and more platters in a drive mean more mass for the motor to turn, so more powerful motors are required. The same is true of higher-speed drives. Finally, with power management becoming more of a concern today, users increasingly want hard disks that will spin up from a stopped position to operating speed quickly, which also requires faster or more powerful motors.

One important quality issue that has become a focus of attention with newer hard disks is the amount of noise, heat and vibration they generate. The reason for this becoming more of an issue is the increase in spindle speed in most drives. On older hard disks that typically spun at 3600 RPM, this was much less of a problem. Some newer drives, especially 7200 and 10,000 RPM models, can make a lot of noise when they are running. If possible, it’s a good idea to check out a hard disk in operation before you buy it, to assess its noise level and see if it bothers you; this varies greatly from individual to individual. The noise produced also varies to some extent depending on the individual drive even in the same family. Heat created by the spindle motor can eventually cause damage to the hard disk, which is why newer drives need more attention paid to their cooling.

A critical component of the hard disk’s spindle motor that has received much attention recently due to concerns over noise, vibration and reliability is the set of spindle motor bearings. Bearing are precision components that are placed around the shaft of the motor to support them and ensure that the spindle turns smoothly with no wobbling or vibration. As hard disk speeds increase, the demands placed on the bearings increase dramatically. Many of the noise and heat issues created by fast motors are related to the bearings, so engineers are constantly trying to improve them.

Most hard disk motors use ball bearings. These are small metal balls that are placed in a ring around the spindle motor shaft; you have no doubt seen them used in many different applications outside the PC. They are also used elsewhere inside the PC, such as higher-quality power supply fans. Some hard disks use special fluid-dynamic bearings instead of ball bearings. Here, the metal balls are replaced with a thick oil, which reduces noise significantly because the metal-to-metal of ball bearings is removed. It also theoretically greatly increases bearing life, though ball bearings should have a life exceeding the hard disk’s normal service life anyway.

Data recovery Salon welcomes your comments and share with us your ideas, suggestions and experience. Data recovery salon is dedicated in sharing the most useful data recovery information with our users and only if you are good at data recovery or related knowledge, please kindly drop us an email and we will publish your article here. We need to make data recovery Salon to be the most professional and free data recovery E-book online.

World’s Top Data Recovery Hardware Tools

Easy to use at good price

Recover SATA, IDE, External HDDs, NVME SSDs, etc Order Now here

POTABLE DEVICE & NVME SSD RECOVERY TOOL

Recover USB Device and NVME SSDs at high speed! Read Details here.

DFL-PCIE DATA RECOVERY RECHARGE

Best data recovery hardware tool to start a data recovery business, read details here

RECOVER SCRATCHED HDDS

Recover lost data from scratched hard drives, read details here.

SURFACE PRO. RECOVERY

BEST HEAD REPLACEMENT TOOLS

The most cost-effective head replacement tools for Seagate, WD, Samsung, Hitachi, Toshiba, Fujitsu