What data recovery tools to buy if you want to start a data recovery business?

Free video data recovery training on how to recover lost data from different hard drives?

Where to buy head and platter replacement tools at good prices?

Data recover case studies step by step guide

I want to attend professional data recovery training courses

When we are dealing with hard drive clean room data recovery cases, it’s very important and necessary to understand each part of the hdd inside. You need to know what are they and what they are used for. When you are installing and uninstalling the components, you know all the details to take care of so that the data is not getting into the risk of permanent loss.

HDD is a precision mechanism and in order to work it requires very clean air inside. During work HDD may create some very small particles of metal and oil inside. To clean air immediately a drive uses Recirculation filter. This hi-tech filter permanently collects and absorbs even finest particles. The filter located on the way of air motion created by platters rotation.

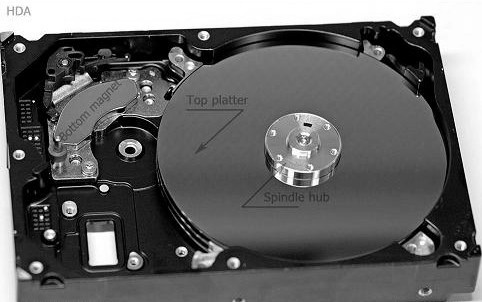

HDDs use very strong Neodymium magnets. Such a magnet is so strong it could lift up to 1300 times its own weight, so don’t put your fingers between magnet and steel or another magnet – it can develop great impact. You can see on this picture there is a HSA stopper on the magnet. HSA stoppers limit HSA movements, so heads wouldn’t bang on the platters clamp and on the other side they wouldn’t just fly off the platters. HSA stoppers may have different construction but there are always two of them and they always present on modern HDDs. On this drive the second HSA stopper located on HDA under the top magnet.

There is the other HSA stopper. And you also can the second magnet. The Voice coil is a part of HSA, Voice coil and the magnets form Voice Coil Motor or VCM. VCM and HSA form the Actuator – a device which moves the heads. Tricky black plastic thingy called Actuator latch is a protection device – it will release HSA when drive un-parking (loading) heads normally and it should block HSA movements in the moment of impact if drive was dropped. Basically it protects (should, at least) heads from unwanted movements when HSA is in parking area.

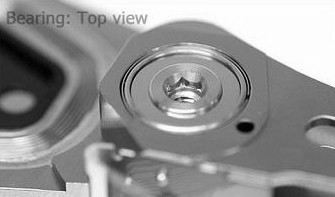

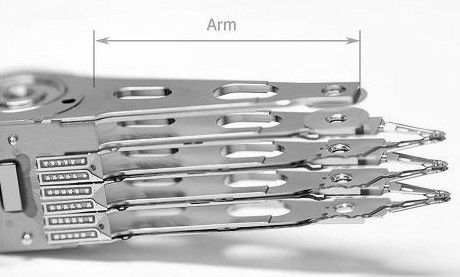

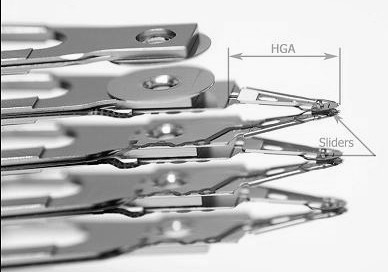

HSA has precision bearing to make movements nice and smooth. The biggest part of HSA milled from piece of aluminum called the Arm. Heads Gimbal Assembly or HGA attached to the Arm. HGAs and Arms usually produced on different factories. Flexible orange widget called Flexible Printed Circuit or FPC joins HSA and plate with heads contacts.

The gasket makes connection airtight. The only way for air to go inside HDA is through the breathing hole. On this drive contacts covered with thin layer of gold, for better conductivity.

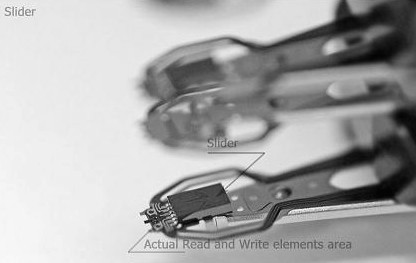

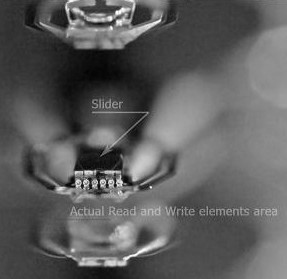

The black small things at the end of HGAs called Sliders. In many sources you can find that sliders claimed as actual heads but a slider itself is not a head it’s a wing which helps read and write elements fly under the platter’s surface. Heads flying height on modern HDDs is about 5-10 nanometers. For example: an average human’s hair is about 25000 nanometers in diameter. If any particle goes under the slider it could immediately overheat (because of friction) the heads and kill them that’s why clean air inside HDA is so important. The actual read and write elements located at the end of the slider and they are so small that can only be seen under a good microscope.

As you can see slider’s surface is not flat, it has aerodynamical grooves. These grooves help a slider fly on the certain height. Air under the slider forms Air Bearing Surface or ABS. ABS makes slider fly almost parallel to the platter’s surface. There is very important part of HSA which we haven’t discussed yet. It called the preamplifier or preamp. The preamp is a chip, which controls heads and amplifies signals from/to them.The reason why the preamp located inside HDA is simple – signals from heads are very weak and on modern HDDs have more than 1GHz frequency, if take the preamp out of HDA such weak signals wouldn’t survive, they will disappear on the way to PCB.

The preamp has much more tracks going to the heads (right side) than to the HDA (left side), it’s because HDD can work only with one “head” (pair of read an write elements) at a time. HDD sends control signals to the preamp and the preamp selects the head which HDD needs at the current moment. This HDD has six contacts per “head”, why so many? One contact is for ground, other two for read and write elements. Other two for microactuators – special piezoelectric or magnetic devices which can move or rotate slider, it helps tune up heads position under a track. And finally the last contact is for a heater. The heater can help adjust heads flying height. The heater can heat the gimbal – special joint which connects slider to HGA, the gimbal made from two stripes of different alloys with different thermal expansion. Once gimbal got heated it bents itself toward platter’s surface and this action reduces flying height. After cooling down the gimbal straights itself.

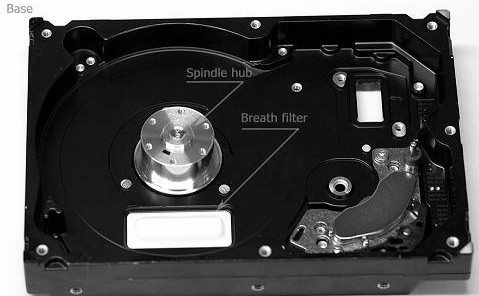

The platters clamp squeezing platters into the platters packet, so they wouldn’t move.Platters sitting on the spindle hub, the platters clamp creates enough friction to hold platters on the hub when spindle rotates.

The spacer ring is a precision detail made of non-magnetic alloy or polymer. The breath hole located right under the breath filter. Because air from outside definitely has dust the breath filter has several layers of filtration and it’s much thicker than recirculation filter, it also may have some silica gel inside to reduce air moisture.

Comments are closed

Sorry, but you cannot leave a comment for this post.